One of the world's leading loT companies is using Radan software in a pilot project to ensure it gets the best terms from sheet metal component suppliers. Bosch Packaging Technology GmbH is part of the global Bosch Group. Recently, the company invested in Radan to determine exact costs for the packaging machines they use in the food and pharmaceutical industries. pharmaceutical industry. The company has outsourced the production of the required sheet metal components. Dominik Bach, at Bosch Packaging's headquarters in Waiblingen, is responsible for the Material management of sheet metal products.

Dominik Bach, Material Field Management at Robert Bosch Packaging Technology GmbH, says: "Thanks to Radan, we benefit from a reduction in the overall lead time of an order by five to eight days.

Bach says that Radan has solved an important problem for them: "Our suppliers were unable to give us accurate and quick calculations for the sheet metal parts. We often received late and incorrect quotations and sometimes the same part was offered at different prices. That's why we created a fixed order pattern with Radan.

Instead of sending a request to suppliers, getting a quote and then placing the order, we can now tell the supplier the exact cost of the part and the individual workflow." To achieve this, Bosch invested in various Radan modules: Wheel Import, Wheel Profiles, Wheel Manager and Wheel Quote, which automate the calculations based on sheet metal technology.

Select the best supplier for the individual project

Bosch's design and development department supplies 3D models, which are then imported and automatically processed via Radan. The laser cutting time and material consumption for the order specification are then calculated.

"Using predefined formulas, the costs of other individual work processes are entered using Radquote, including bending, straightening, deburring, welding, glass bead blasting, drilling, purchased parts as well as labor and shipping costs."

These calculations determine the price for the machine cycle times and all subsequent work.

The only variable is the hourly rate for the suppliers' workshop workers. This means that the company can set the final price it is willing to pay. "The sheet metal software provides us with realistic figures on which to base our calculations," says Bach.

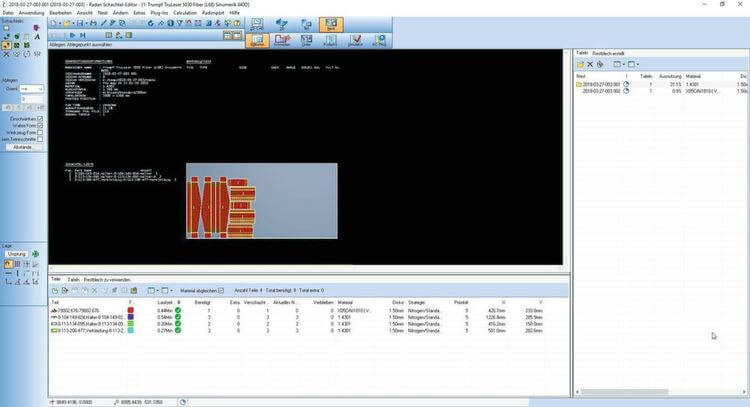

The Radan software in use at Bosch.

The Radan software in use at Bosch.

If a supplier has higher personnel costs, Bosch helps them with the company's own supplier development options, for example by implementing fast change processes or using workshops. The aim is to optimize their production in order to be competitive with another supplier with lower personnel costs. "For example, a supplier with fast laser cutting but lower welding performance would not get the order for a project that requires more welding work. Radan gives us the opportunity to always choose the best supplier for the project." Bosch sends the calculations to the suppliers together with the order and the STEP files of the component. Bach goes on to say that this approach is a win-win situation for both Bosch and the supplier. Bosch benefits from a reduction in the overall lead time of an order by five to eight days, constant price and planning security and cost savings thanks to the best possible placement of orders depending on supplier strengths.

Increase the efficiency of procurement processes

"There are also advantages for our suppliers: No calculations or quotations are required, no sales effort is needed to obtain an order from Bosch and we offer a multi-year contract to manufacture the components," explains Bach. Another major advantage is that the software shows each supplier its individual strengths. "For example, if a tell requires several welding operations, Radan shows which supplier achieves the best welding performance. This means that we can not only decide on the price, but also select the most suitable supplier for each order. This means that the suppliers receive orders from us that reflect their individual strengths.

Detlef Baier (who works in procurement at Bosch) uses Radan to place orders with suppliers.

Dominik Bach and his team are currently using Radan in this way in a pilot project. If the approach proves successful, as early indications suggest, the solution is likely to be rolled out to other Bosch plants around the world. "Radan could ultimately have a significant impact on the efficiency of our procurement processes worldwide," Bach concludes.