Parts of a unique multi-object telescope are measured with the EDGECAM software solution and a coordinate measuring machine (CMM) from Hexagon.

The UK Astronomy Technology Centre (ATC) is working on two different instruments that will help astronomers learn much more about the universe than is currently known. Some of the parts have been manufactured using toolpaths created using EDGECAM CAD/CAM software and are then aligned with the highest precision using a Hexagon coordinate measuring machine (CMM). Will Taylor, Instrument Scientist at the UK ATC, explains that the instruments will be installed in the VLT (Very Large Telescope) at the Paranal Observatory in Chile - one of the most productive ground-based telescopes in the world.

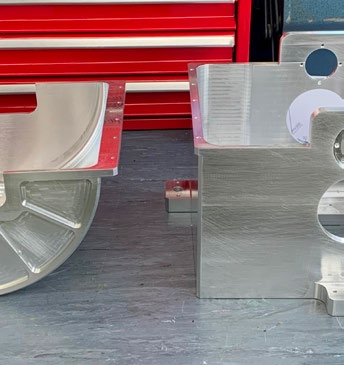

Eris component

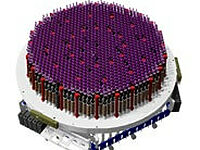

One of these is called MOONS - Multi-Object Optical Near-infrared Spectograph. It can be used to observe many astronomical objects simultaneously and collect information about each individual object at the same time. The UK ATC assembles all the parts for the MOONS at its Edinburgh site. Will Taylor explains that this is a particularly novel and exciting project. "It will allow astronomers to look at 1,000 objects at once and in the infrared spectrum. This is the first time anyone has combined high multiplexing with infrared." Due to the vast distances involved, the light we see from the stars today has actually been traveling for millions of years. MOONS will now take scientists even further away for the first time - possibly around 10 billion light years, allowing them to create a map of a large section of the universe.

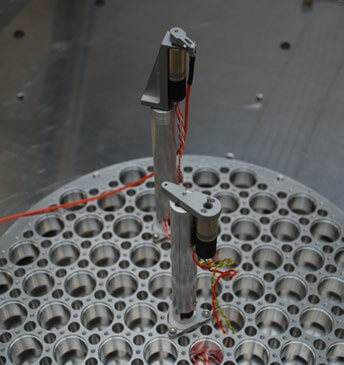

At the heart of the instrument are one thousand small positioning robots, which are used to precisely align the optical fibers with the target object.

The light is then guided along these fibers into the spectrograph, where it is split into three different wavelength channels and then scattered to provide spectra in each channel simultaneously. EDGECAM and the Hexagon CMM play an important role in the manufacture of the highly complex components. Manufacturing engineer Richard Kotlewski is responsible for producing the majority of the internal components used in the structure for the digital mirror device.

MOONS panel prototype fiber positioner Eris component

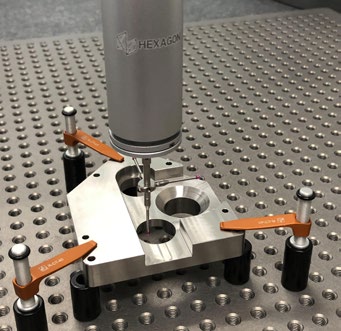

Programming the 75 mm square components for the precise calibration system, which is a fundamental part of the instrument, took only a few hours with EDGECAM.

Kotlewski imported the 3D model and drawing into EDGECAM and decided how the part should be manufactured, as well as the machine intended for it. "Then I set up the datum and used EDGECAM's powerful Feature Finder function and let the software generate the perfect toolpaths automatically. High precision in the production of the parts was extremely important as accuracy was absolutely critical for the optical alignment of these parts."

As the parts are used to hold the optics, calibration was critical to ensure that the incident light was going to the right place. This was achieved using the Hexagon Global CMM, which checks the holes and positional tolerances of the components in the assembly. The Astronomy Technology Center's second Very Large Telescope (VLT) project is ERIS - Enhanced Resolution Imager and Spectograph - which uses the adaptive optics of the main telescope to remove atmospheric distortions when hunting for planets outside our solar system. "Basically, it takes the twinkle out of the stars. This is achieved with a mirror whose surface shape is adjusted hundreds of times per second. This means that the image quality is incredibly high, without any distortion," says Will Taylor. As a member of an international consortium each producing specific mechanisms, he says the UK ATC's role for ERIS was to build the new diffraction-limited camera system, which was coupled to the optics produced in Italy. Richard Kotlewski explains that some of the camera's parts, made from 6082 aluminum, were produced on their 5-axis Haas VF5 machine tool. "Due to their complexity - the top half is quite thin-walled as we are limited in the weight of this instrument - the programming time for each component was about one day and the machining was two days due to the amount of material removed." He uses EDGECAM's powerful 'wavy roughing' strategy to make deeper cuts with less distortion due to the reduced offset, while still achieving optimum material removal rates. For these components, the Hexagon CMM is used in a different way. Although they don't make all the components for this particular assembly, they are responsible for the entire finished instrument. "We have to check the parts we make, along with parts from other members of the consortium, and make sure everything is precisely aligned." The mechanisms have to be within ten micrometers of each other so that everything fits together. Using the Hexagon CMM ensures this. "This work takes over a week. Each individual mechanism is placed on customizable supports attached to the optical bench. Measurements are taken to determine the center of the mechanism and ensure that it is square and parallel. Shims are made to bring the mechanism into the correct position. The mechanism is then checked again. Only when we are completely satisfied with each individual component do we put them all together and carry out a final visual check. Without the CMM, we wouldn't be able to do this important part of the work." Richard Kotlewski concludes: "It's a real privilege to work on such ground-breaking astronomical projects - I'm creating components that make it possible to study the formation and evolution of galaxies over most of the history of the universe with unprecedented accuracy."

MOONS model of the fully assembled panel.

Richard Kotlewski

Summary

Company: UK Astronomy Technology Center

Internet: www.technologysi.stfc.ac.uk/Pages/United-Kingdom-Astronomy-Technology-Centre.aspx

Business: development of scientific instruments and facilities for ground and space-based astronomy

Achievements:

- Novel precision

- Deeper cuts and less strain on the

metal at optimum removal rates

- Fast and precise tool paths

Hexagon is a global leader in sensor, software and autonomous solutions. We use data to increase efficiency, productivity and quality for applications in industrial manufacturing, infrastructure, security and mobility. With our technologies, we are shaping increasingly connected and autonomous ecosystems in urban environments and manufacturing, ensuring scalability and sustainability for the future.

Hexagon's Manufacturing Intelligence division uses data from design and engineering, manufacturing and metrology as the basis for solutions to optimize manufacturing processes. For more information, visit hexagonmi.com. Learn more about Hexagon (Nasdaq Stockholm: HEXA B) at hexagon.com. You can also follow us @HexagonAB.