Providing the customer with a quote as quickly as possible - that's what contract manufacturers want. The Radan Designer is a tool for data preparation and the creation of sheet metal parts for contract manufacturing.

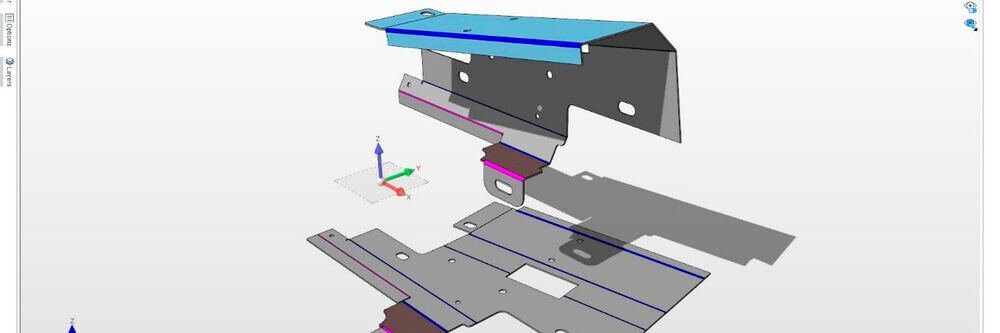

Radan Designer is the new basic tool in the Radan product line. In Designer, contract manufacturers can quickly repair imported 3D CAD components and transform them into a real sheet metal part. (Image: 3D Concepts) The problem is well known; contract manufacturers receive 3D CAD data from their customers that has not been designed as a sheet metal part or has been transferred with missing bending radii, corner clearances or notches. On the one hand, this makes it very time-consuming to create a dedicated quotation and, on the other hand, it is not possible to get the sheet metal part quickly into a cut-to-size nesting or for bending. The challenge as a contract manufacturer is therefore to determine the costs as quickly as possible in order to prepare an adequate quotation for the customer. Because customers don't like to wait. If the order is placed, it must also be ensured that the order can be processed on the laser, punching and bending machines without any problems.

Many parametrically structured CAD systems are too rigid to repair such "problem parts" flexibly. In addition, it may be necessary to make many inquiries to the customer, which in turn costs time and money. A last resort is then to either reject the order for the sheet metal part or the sheet metal assembly or to laboriously redesign the corresponding component. This is where the Radan Designer comes in. It is the new basic tool in the Radan product line. In the Designer, contract manufacturers can quickly repair imported 3D CAD components and transform them into a real sheet metal part. Complete sheet metal parts and assemblies can also be designed. The special feature here is that the CAD data is not parameterized (i.e. provided with many restrictions), so that free and intuitive working is possible. For example, a surface can be marked and then simply moved using a slider. Angles can be marked and also changed dynamically using an angle slider. Or two adjacent surfaces can be marked and separated for notching with just one click. The same scheme can be applied to bending radii and corner releases. If the sheet metal part is correct, the cut is unwound directly. Material shortening values based on the K-factor or the new SFX cloud platform with precise shortening values depending on the material and angles are available.

Radan-Designer is also equipped with two neutral, digital twins of folding benches with a standard tool set. This enables the designer to check whether the repaired or created sheet metal parts are technically feasible on a folding bench based on the 3D simulation, even without bending knowledge. A 2D workshop drawing, if still necessary today, can also be created quickly with just a few clicks. Using the Radan modules for bending and cutting, the repaired or newly created sheet metal parts or assemblies can be transferred directly to the cut-to-size nesting or a bending program can be simulated and programmed using the Radan offline bending program.