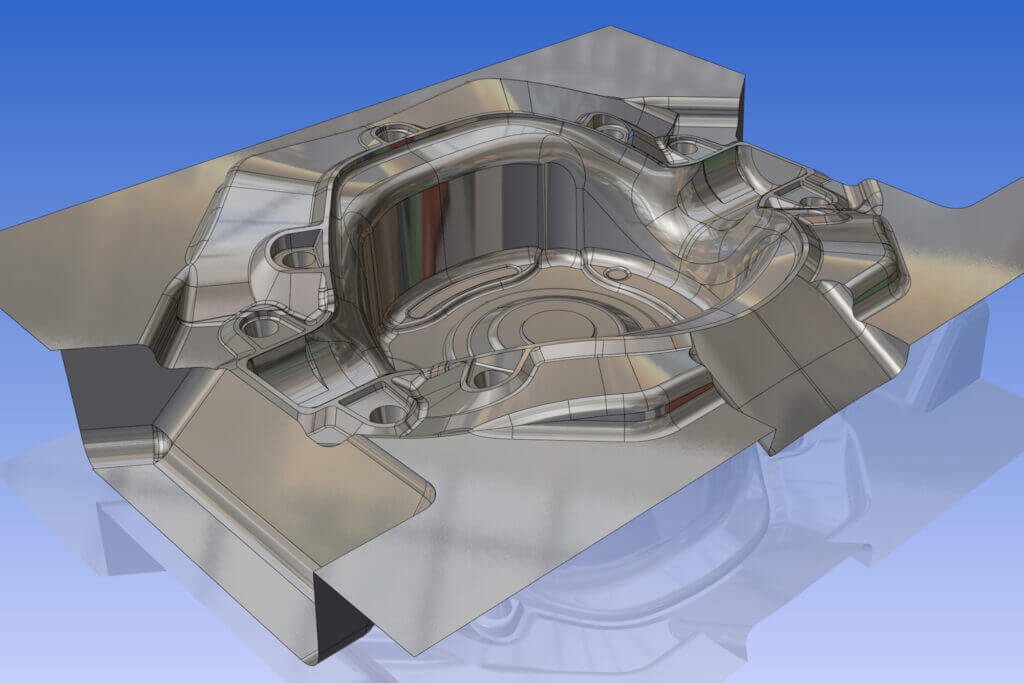

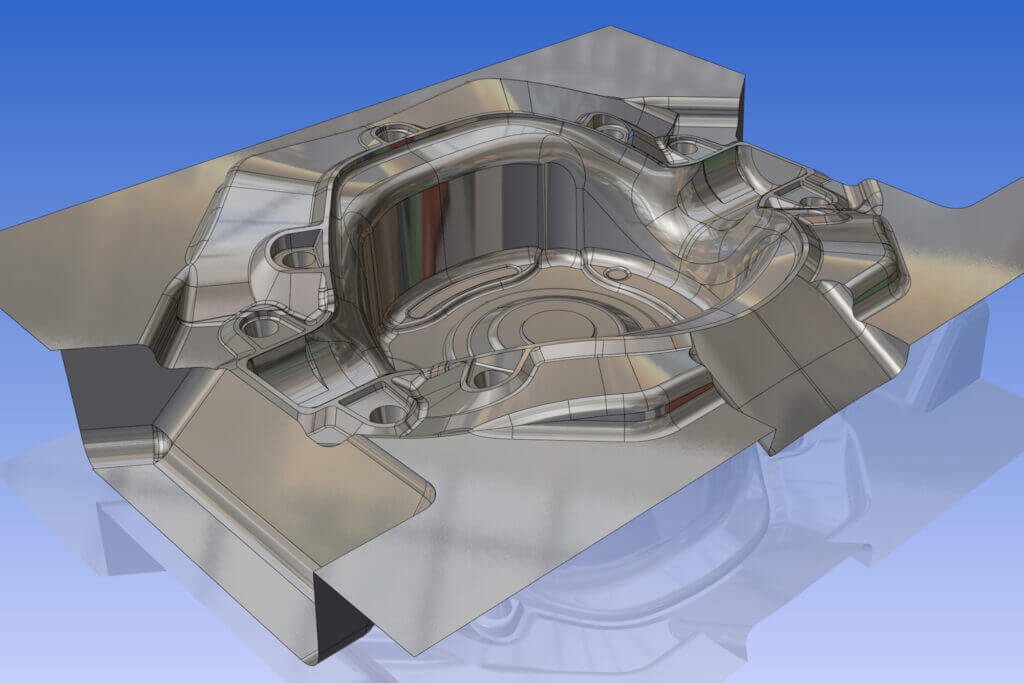

Designer bridges the gap between CAD and CAM. From fixture design to the repair and modification of parts, Designer is the ultimate CAD solution for geometry through to production. The solution features various modeling functions for solids, surfaces and sheet metal, 2D drawing creation, design automation using macros and scripting, and a link to Hexagon's CAM software and reverse engineering capabilities.

With Designer, changes can either be completely free-form or made using measurements of existing geometries. Knowledge of the original model's construction methods is no longer required and design changes are not limited to the original creation methods. Direct modeling gives users complete design freedom, whether they are creating a new part or adapting an existing design in one of the myriad CAD formats supported by Designer.

Designer's intuitive user interface and searchable functions ensure a quick and easy introduction to smarter manufacturing. If you have any questions, Designer's comprehensive integrated help function quickly provides the right answers.

Designer's direct modeling allows geometry to be brought into the desired shape by dragging and sliding. Designer offers the possibility to implement creative ideas immediately. This enables a flexible and dynamic way of working that meets the requirements of different projects.

Creation of two-dimensional shapes using free-form input. While the user can rely on the traditional methods of coordinate-based input, freeform sketching interacts intelligently with the surrounding geometry. It speeds up the creation of sketches while maintaining maximum flexibility for future changes.

We offer a comprehensive service to ensure smooth integration. Our experts ensure that Designer is used to its full extent and that you can realize the benefits of the CAD solution accordingly. If you have already integrated Designer, our regular training courses allow you to refresh your know-how and keep up to date with the latest developments.

All information on the various Designer modules at a glance can be found here

Designer automatically creates the boundaries of faulty or missing surfaces, making it easy to identify and recreate new surfaces using comprehensive surface editing programs. Repairing defective solids and closing a surface model to create a solid model prevents subsequent design problems.

The incoming CAD data often contains geometric features that are not required for the conventional machining process. Post-machining processes such as laser engraving, electrode marking and other techniques are often depicted on the original CAD model. Although such markings are important for the CAD design and can also be found in the finished component, they often make the CAM programmer's work more difficult. With Designer, these unnecessary features can be suppressed or separated from the subsequent processing steps with just one mouse click.

If necessary, in addition to the suppression of certain features, the geometry should also be simplified in various phases of the machining process. Removing certain model areas, such as cutting features, improves the machining process. Direct modeling greatly simplifies this process without being limited by a previous design method or feature tree. Model variants for each process phase can be created more easily. Machining results are achieved faster and are of higher quality.

Designer offers a variety of techniques for creating geometries that are crucial for model preparation. Programmers benefit more than ever from the simple yet powerful surface creation techniques.

Designer supports the import of 2D data, such as DXF and DWG files. These can be quickly and easily converted into production-ready 3D models. The imported 2D data automatically creates outlined profile areas, making the conversion from 2D to 3D easier than ever.

Designer's sketching functions allow the creation of two-dimensional shapes using freeform input. While the user can rely on the traditional methods of coordinate-based input, freeform sketching interacts intelligently with the surrounding geometry.

Designer's surface module allows the creation and machining of complex freeform surfaces such as raised, helical, rounded and tangential surfaces. The module also includes more specialized tools for surface creation, such as cutting parts into cavity and core, parting and cleavage planes, bend relief for reducing and modifying complex bends, and creating large offsets from complex parts.

Designer's special 'Sheet Metal' module provides powerful functions for transforming parts from solid or surface models into production-ready sheet metal parts. It takes into account production parameters and provides special tools for calculating all the necessary sheet metal processing steps.

This optional module of Designer was developed by engineers with extensive experience in tool and mould making and convinces with special and intuitive functions for optimized electrode creation.